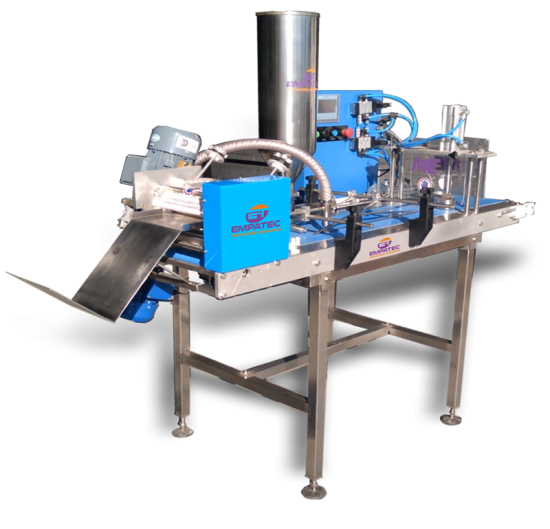

Empanada Machine ME Model

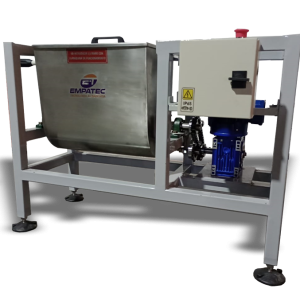

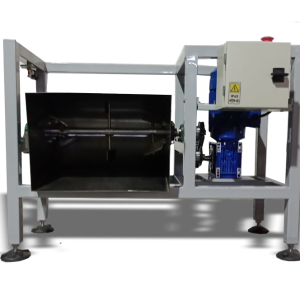

The main characteristics are included bellow:

Designed to supply either medium- or high-sized production

Controls through touchscreen and PLC (Programmable Logic Controller)

Filling dosing system

Works with a sheet of dough, doesn’t need cut disc feeding

Interchangeable molds in different sizes and shapes

Single-phase, low power consumption

Approximate production of 2000 units per hour, depending on product size

It is fitted with recipes customized to mold size, therefore avoiding the time-consuming

regulation they require.

Description

The empanada forming equipment ME Model, is an automated machine which complies with international standards, both regarding its design and its safety.

The equipment works with a sheet of dough, which is inserted into the dough sheeter, and is then transported by a conveyor belt where it will be filled by means of a dosing device, and subsequently folded, stamped and cut by customized interchangeable molds, forming the desired product that will be manually removed to be stowed in their respective trays.

Safety:

The equipment is fitted with e-stops for operator and machine safety.

Download the brochure of the Empanada Machine Model ME