Flow-Pack Type Packing Machine EFP Model

General features:

It is fitted with safety systems, both for the operator and the machine

It produces approximately 45 packages/min if a 125mm-long product is packed

The material used to form the container is bioriented polypropylene (PPB0).

Interchangeable shoulders to pack different products

Engines:

Feeding conveyor belt engine: 0.25HP

Traction engine: 0.25 HP

Description

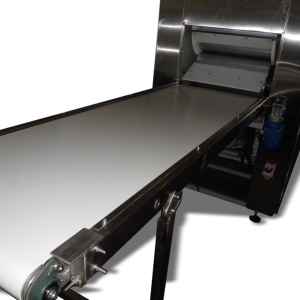

Feeding Procedure:

The product is placed on a feeding conveyor belt against a lateral adjustable guide sized to

match the product, then the machine conveys it up to an optical positioner which centers the

product so that it accurately matches the printed container. Once the product is fed into the

forming shoulder of the container, it is pulled and welded longitudinally, and finally it is crossed

sealed and simultaneously cut into units.

This equipment has the capacity to pack different size products, their width ranging from 80 to 320mm, just by changing the forming device (ask for especial sizes).

Unlike other packing machines available in the market, this model senses the presence of product, and automatically starts to operate only when it is present, so that there is no room for feeding mistakes, nor the risk of wasting any film. The machine runs at a constant speed, but does not operate when there is no product to be packed.

Download brochure packing Machine Flow Pack